The demand for accuracy, efficiency, and reliability in manufacturing has never been greater. High-quality precision manufacturing is revolutionizing production processes, enabling businesses to create complex components with unmatched precision and consistency.

What Is High-Quality Precision Manufacturing?

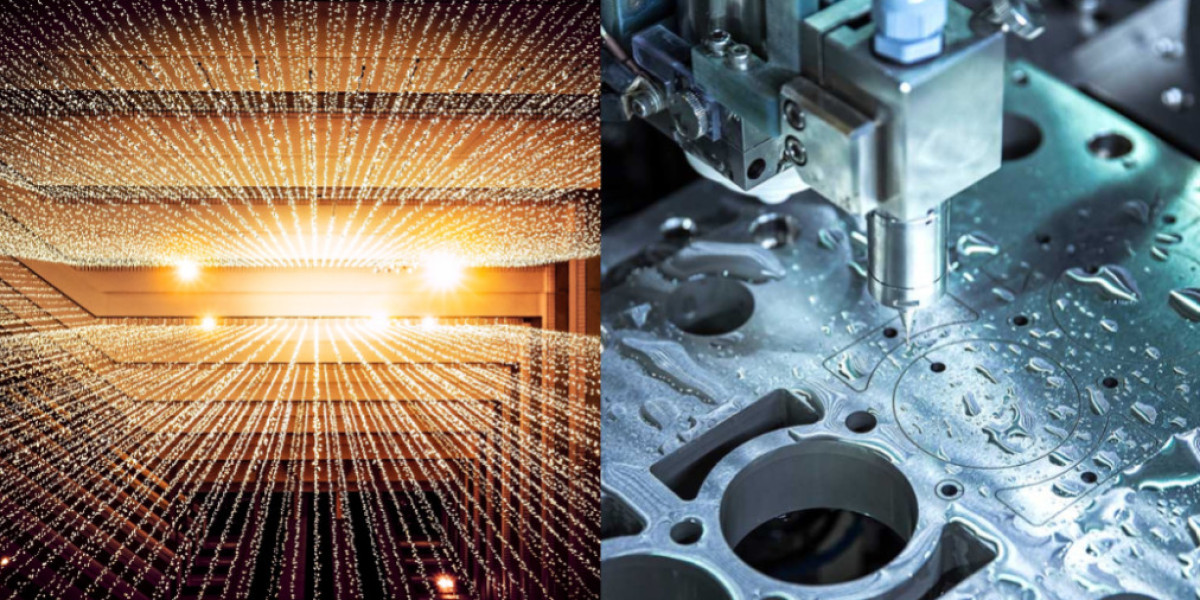

High-quality precision manufacturing leverages advanced techniques such as CNC machining, AI-driven automation, and laser technology to deliver exact specifications with minimal error. This approach ensures superior product quality across multiple industries.

Advantages of High-Quality Precision Manufacturing

Unparalleled Accuracy – Delivers precise components with tight tolerances.

Cost Optimization – Reduces waste and lowers production costs.

Increased Efficiency – Automation streamlines production, reducing time and labor costs.

Industry Versatility – Applied in aerospace, healthcare, automotive, and electronics sectors.

Sustainable Manufacturing – Supports eco-friendly production with minimal material waste.

Technologies Advancing High-Quality Precision Manufacturing

State-of-the-art technologies enhance manufacturing precision and efficiency, including:

1. CNC Machining

A fundamental aspect of high-quality precision manufacturing, CNC machining ensures repeatable, high-precision production with minimal human intervention.

2. Additive Manufacturing (3D Printing)

This innovative approach enables rapid prototyping and cost-effective production of intricate parts.

3. AI-Powered Quality Control

Artificial intelligence enhances defect detection, ensuring flawless product output.

4. Robotic Automation

Automated systems boost efficiency, eliminate human error, and improve workplace safety.

5. Laser & Micro-Machining

Laser precision technology provides intricate detailing and superior component fabrication.

Industries Benefiting from High-Quality Precision Manufacturing

Precision manufacturing is essential in various sectors, ensuring compliance and product excellence:

Aerospace & Defense – Requires precision for aircraft and defense components.

Medical & Healthcare – Produces high-accuracy surgical tools and implants.

Automotive Manufacturing – Ensures reliability in engine and safety components.

Electronics & Semiconductor Industry – Supports microchip and circuit board fabrication.

The Future of High-Quality Precision Manufacturing

With advancements in Industry 4.0, high-quality precision manufacturing is incorporating AI, IoT, and cloud-based automation, driving innovation and efficiency in production processes.

Conclusion

Investing in high-quality precision manufacturing helps businesses improve product quality, optimize costs, and maintain a competitive edge in the evolving industrial landscape.

Explore the latest innovations in precision manufacturing and stay ahead in the market today!